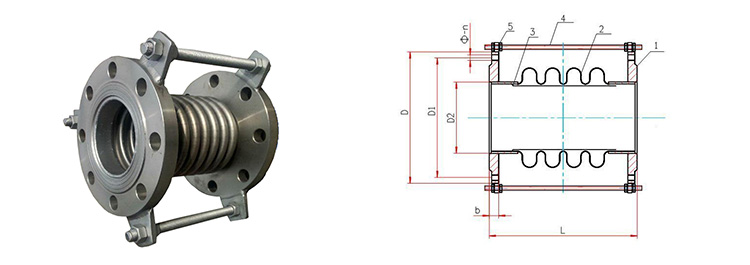

Norminal diameter:DN20-DN2000MM

Pressure rating:PN10/16/25/40

Working temperature:0℃~+420℃

Connection: flange,Tube

In the industrial world, Metal Expansion joints are among the most critical components of flue duct and pressure piping applications.Metal expansion joints can withstand the design temperatures, pressures, as well as, provide the capacity necessary to absorb thermal growth of the piping system. In some cases, the pressure thrust of a pipe expansion joint must be restrained by the use of tie rods, hinges or gimbal while allowing the bellows to move through its design deflections.Count on CHANGHONGSHENG Expansion Joints to meet your complete requirements with products that are competitively priced, and proven to provide extended service life versus competitive models. CHANGHONG manufactures metallic and non-metallic piping and flue duct Expansion Joints to the highest quality standards.

Expansion Joint Product Testing:

CHANGHONG Bellows, does extensive physical testing ranging from X-Ray tests and Hydrotests to Helium Leak tests (using a mass spectrometer.) Each bellows and pipe expansion joint unit goes through in-process quality control using a system of travelers. Final in-house inspection and testing are performed prior to shipping. Our manufacturing shop also has ASME Section VIII CODE certification.

Fatigue Testing (also known as Cycle Testing)

Fatigue testing is essentially verifying how many cycles a bellows can withstand before failing. The bellows is placed on the “cycle-test machine” and bolted to a hydraulic plunger. Each cycle is counted as the bellows is compressed and returned to neutral.

View a Fatigue Test Verifying a Cycle Life of 30,000 (VIDEO)

Burst Testing

The objective of the burst test is to determine the ultimate pressure resistance, primarily conducted on bellows. Normally, hydraulic pressure is slowly increased until failure occurs. Pressure balanced pipe expansion joints are designed to maintain a constant volume through the use of a compensating bellows.

| DN | Quantity of ripple | Pressure grade(Mpa) | Available area of corugated tube | Maximum extemal diameter(mm) | Length | ||||

| 0.6 | 1 | 1.6 | 2.5 | ||||||

| Axial compensation length mm/ toungness N/mm | Flange JZ/F | Connection JZ/J | |||||||

| 32 | 8 | 22/26 | 20/26 | 18/63 | 16 | 225 | 160/250 | 264/280 | |

| 40 | 8 | 22/44 | 20/44 | 18/89 | 15/98 | 23 | 244 | 164/259 | 269/289 |

| 50 | 8 | 22/51 | 20/70 | 18/70 | 15/106 | 37 | 259 | 172/276 | 282/306 |

| 65 | 8 | 30/35 | 26/44 | 22/55 | 15/138 | 55 | 270 | 215/294 | 300/322 |

| 80 | 8 | 36/26 | 34/33 | 28/41 | 19/68 | 81 | 284 | 240/338 | 344/366 |

| 100 | 6 | 45/60 | 40/75 | 35/93 | 25/54 | 121 | 304 | 235/317 | 323/345 |

| 125 | 5 | 42/47 | 38/59 | 34/74 | 29/117 | 180 | 334 | 282/314 | 316/342 |

| 150 | 8 | 71/43 | 64/51 | 54/59 | 50/56 | 257 | 364 | 356/399 | 402/427 |

| 200 | 6 | 65/44 | 59/52 | 53/58 | 48/78 | 479 | 442 | 340/402 | 402/426 |

| 250 | 4 | 65/34 | 59/42 | 52/45 | 47/55 | 769 | 507 | 315/379 | 415/379 |

| 6 | 97/21 | 87/35 | 79/39 | 71/47 | 393/459 | 493/399 | |||

| 300 | 4 | 65/55 | 59/59 | 52/65 | 47/55 | 1105 | 562 | 366/427 | 466/467 |

| 6 | 97/35 | 87/37 | 79/41 | 71/457 | 464/525 | 564/565 | |||

| 350 | 4 | 65/62 | 59/67 | 52/74 | 47/81 | 1307 | 622 | 397/452 | 497/492 |

| 6 | 97/41 | 87/44 | 79/48 | 71/47 | 509/564 | 609/604 | |||

| 400 | 6 | 65/58 | 59/62 | 52/68 | 47/75 | 1611 | 340 | 412/478 | 512/518 |

| 8 | 97/39 | 87/43 | 79/47 | 71/52 | 420 | 522/588 | 622/628 | ||

| 450 | 6 | 97/35 | 87/37 | 79/41 | 71/45 | 1972 | 340 | 403/498 | 503/523 |

| 8 | 145/22 | 131/23 | 118/35 | 108/28 | 450 | 503/658 | 603/648 | ||

| 500 | 6 | 97/64 | 87/68 | 79/75 | 71/82 | 2445 | 340 | 431/523 | 531/554 |

| 8 | 145/37 | 131/39 | 118/43 | 106/48 | 450 | 531/665 | 631/742 | ||

| 600 | 6 | 97/80 | 87/85 | 79/94 | 71/103 | 3534 | 380 | 478/548 | 578/588 |

| 8 | 145/45 | 131/49 | 118/53 | 106/60 | 500 | 658/679 | 758/781 | ||

| 700 | 4 | 97/72 | 87/77 | 79/85 | 71/95 | 4717 | 1110 | 490 | 590 |

| 6 | 145/45 | 131/49 | 118/53 | 106/60 | 690 | 790 | |||

| 800 | 4 | 108/95 | 102/102 | 94/112 | 82/123 | 5822 | 1265 | 502 | 602 |

| 6 | 164/72 | 156/77 | 144/85 | 125/93 | 610 | 710 | |||

| 900 | 4 | 108/90 | 102/97 | 94/107 | 82/117 | 7620 | 1186 | 698 | |

| 6 | 164/65 | 156/69 | 144/76 | 125/84 | 850 | ||||

| 1000 | 4 | 108/98 | 102/105 | 94/116 | 82/117 | 9043 | 1286 | 692 | |

| 6 | 164/65 | 156/71 | 144/81 | 125/84 | 855 | ||||

We use the domestic initiative technology and process way to make a good connection between Chinese-medicine food therapy production and black/ brown sugar. Meanwhile, it will enhance the function of the absorption of nutrients by the human body.